In order to give better protection to steel products, hot dip galvanizing has become a very important method of operation, and hot dip galvanizing equipment has become an indispensable part of the processing process. However, many operators do not operate the equipment well during the actual processing, which will have a relevant impact on the actual production results, so the processing temperature of hot dip galvanizing is very important during operation.

Only when the appropriate temperature can be mastered, the overall production can achieve very good results. In the process of processing hot dip galvanizing equipment, when some small parts are added, the high temperature operation should be selected, and the high temperature operating temperature should be Before 520 to 560 degrees, such temperature can have very good results in the actual processing process, and you should better grasp this problem during the operation of your friends.

Only by adopting high-temperature processing, the processing speed and thickness of small parts can be better grasped. For the processing of some large parts, the temperature of 435 to 460 degrees is very suitable. In actual processing, the temperature of the equipment should be adjusted according to the specific parts and the thickness of the galvanized layer. The device is in a better working state.

It is hoped that every operator can reasonably adjust the processing temperature of hot dip galvanizing equipment. When it is clearly understood in every part of the temperature, the processing can be more idealized. It can be learned from the various parts of the process that the handling of every detail has become a part that cannot be ignored and must be taken seriously.

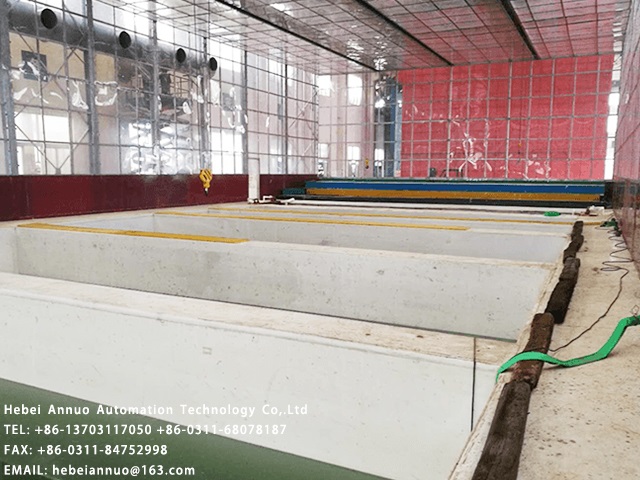

hot dip galvanizing process hot dip galvanization hot dip galvanizing line hot dip galvanizing equipment

hot dip galvanizing process hot dip galvanization hot dip galvanizing line hot dip galvanizing equipment

TEL: +86-13703117050 +86-0311-68078187

FAX: +86-0311-84752998

WhatsApp: 0086 137 0311 7050

WeChat: 13703117050

EMAIL: hebeiannuo@163.com

ADDRESS: Shijiazhuang City,Hebei Province, 051530,China