Nowadays, there are many steel applications. In order to ensure good processing, it is necessary to use as a representative to improve the utilization efficiency of steel. Regarding the hot-dip galvanizing production method, the application of the current application is still very good, and it can have a good effect. So what about such a production line? What are the advantages of processing applications?

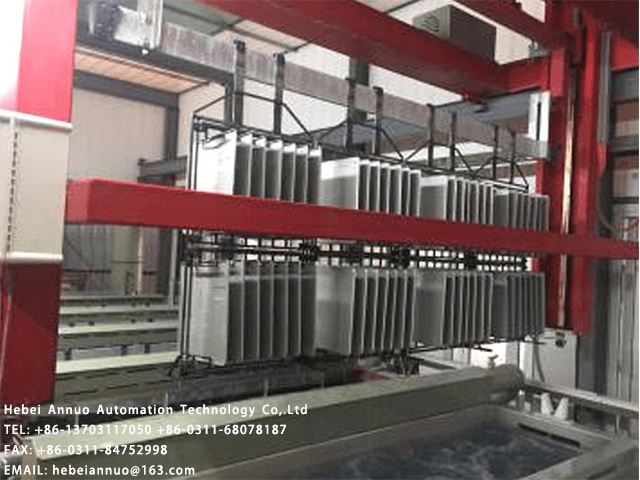

The appearance of Hot Galvanizing Lines is actually relatively early. With the demand of production and processing applications, there are also good transformation and upgrading in function, and the better processing and processing guarantee, the safety protection has been significantly improved. First of all, let's understand the role of hot-dip galvanizing. According to the current production and processing, the principle of hot-dip galvanizing is simple. It is to put the rust-removed steel into the zinc liquid with very high temperature, so that it can produce good protection. Layer, the protection is improved, helping to have better security protection. The protective layer is a metallurgical combination method, which can naturally become a part of the steel surface, has better durability, can guarantee the service life well, and is increasingly becoming an ideal processing and processing representative.

Compared with the traditional steel processing, the hot-dip galvanizing process is more time-saving and labor-saving. After the improvement of the process, it can have better processing efficiency, the construction is more convenient and convenient, and the manpower and time are reduced. Waste. In terms of production and processing, the efficiency is still very good, reducing waste, and meeting the needs of today's production and processing applications.

The advantages of Hot Galvanizing Lines are still relatively high, and they can play a very good role in terms of production and processing. For the development of the production line, we can also have a certain understanding, optimistic about the processing process requirements and process conditions, to ensure better processing efficiency.

TEL: +86-13703117050 +86-0311-68078187

FAX: +86-0311-84752998

WhatsApp: 0086 137 0311 7050

WeChat: 13703117050

EMAIL: hebeiannuo@163.com

ADDRESS: Shijiazhuang City,Hebei Province, 051530,China