The manufacturer that believes to use hot dip galvanization equipment is certain to have certain understanding to hot galvanization, but also be restricted in the most basic understanding only. In the daily use of some equipment maintenance, detection methods are certainly unknown to everyone, the small make up for you to provide some relevant information hope to help you.

How to control the speed of galvanized equipment:

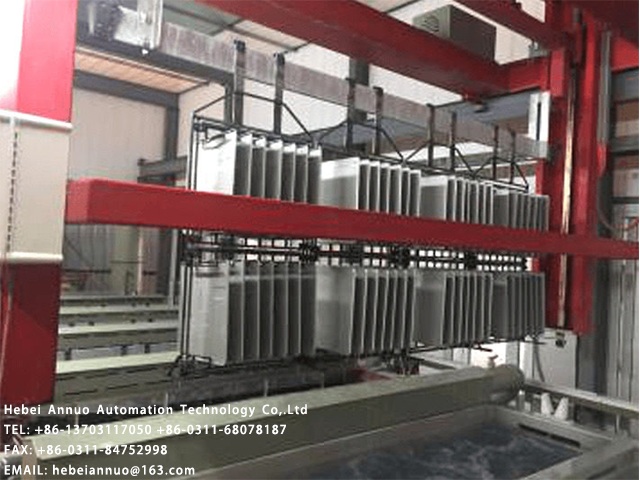

The hot-dip galvanizing equipment is very important for speed control in the process of operation. Speed control can accelerate the output value to achieve faster production, but it is not so easy to ensure the quality of equipment and improve the speed.

Generally speaking, lifting speed of 1.6m-min can achieve good zinc-liquid reflux and surface brightness. However, some special parts have some requirements for speed. Whether it is fast or slow, it can be selected in the interval of 0.7-3.5m-min, and the selected speed interval is acceptable for the parts.

Longer parts require multi-stage speed control. Therefore, it is best to design multi-stage or no-speed change of at least 5 stages for lifting crane to get the best surface quality, zinc consumption standard and production schedule. The lifting speed must be slower than the natural reflux speed, as this will prevent various external damage to the part, such as:

Zinc spines, zinc streamers, streamers. Finally, it should be noted that for longer parts, the inclined immersion part should also pay attention to first in first out galvanizing. How to control the speed of galvanizing equipment to ensure that the film thickness of the whole part is relatively uniform.

How to maintain galvanizing equipment:

Cleans the galvanizing equipment is the most basic daily inspection work, wiped the dust and dirt devices so as to ensure that its surface is clean, can greatly avoid external equipment failure caused by dirt, dust, abrasion, jams, leakage and loss, leakage and other good degrees lower, because often results from problems caused by equipment failure.

Besides, when cleaning galvanizing equipment, it is not only necessary to clean the surface of hot-dip galvanizing equipment, but also need to clean every corner of the hot-dip equipment. If the equipment is found to have problems such as wear, looseness, scars, deformation, cracks, temperature rise, vibration and sound, it needs to be discovered and dealt with immediately.

The above information is provided by anno, a professional hot dip galvanization equipment . If you want to know more about our products, you can consult our customers for further understanding.

TEL: +86-13703117050 +86-0311-68078187

FAX: +86-0311-84752998

WhatsApp: 0086 137 0311 7050

WeChat: 13703117050

EMAIL: hebeiannuo@163.com

ADDRESS: Shijiazhuang City,Hebei Province, 051530,China