The current domestic popular hot galvanizing project is very simple, zinc alloy is produced zinc smelter, simply add a medium frequency coreless induction furnace for intermediate alloy, the original high power induction furnace for melting zinc is modified, open a hole in the middle of the roof and increase a stirring device, match into the intermediate alloy after measuring, mixing, casting.

This production mode is characterized by simple process and easy transformation by using the existing ingot melting furnace, which is widely used in zinc smelters. However, this process has several shortcomings:

According to the heating characteristics of cored induction furnace, it is necessary to have a starting melt furnace. That is, the minimum height of the metal liquid surface in the furnace must ensure that the induction groove of the inductor can be immersed. Therefore, each time with a batch of zinc alloy, casting only about a third (that is, the residual metal level guarantee in rev melt height above), you must add zinc melting, to make the next batch furnace melting. When alloy preparation, stirring and pre-furnace analysis are carried out, the heating or heat preservation can only be stopped. The continuous melting advantage of high-power induction furnace cannot be played out, and the lifting and lifting operation of agitator is difficult.

Due to the diameter of the mixing blade is on the top of the restriction of the open aperture (influence thermal effect), small range of mixing effect on the rectangular furnace is limited, so the mixing of inadequate and blade increases the effect of iron, the uniformity of composition and and had a negative impact on the requirements of all iron content.

When the alloy variety needs to be replaced, it is time-consuming and time-consuming to wash the furnace with a large capacity core induction furnace. When changing the alloy elements, the furnace needs a long continuous operation to complete.

It has an effect on both electric equipment and furnace life. When a large amount of zinc sheet is added into the alloy liquid, the temperature is the lowest and the high power temperature is required. When mixed with the intermediate alloy, the temperature needs to be raised to the maximum, which is not conducive to control in terms of energy consumption and metal burn loss.

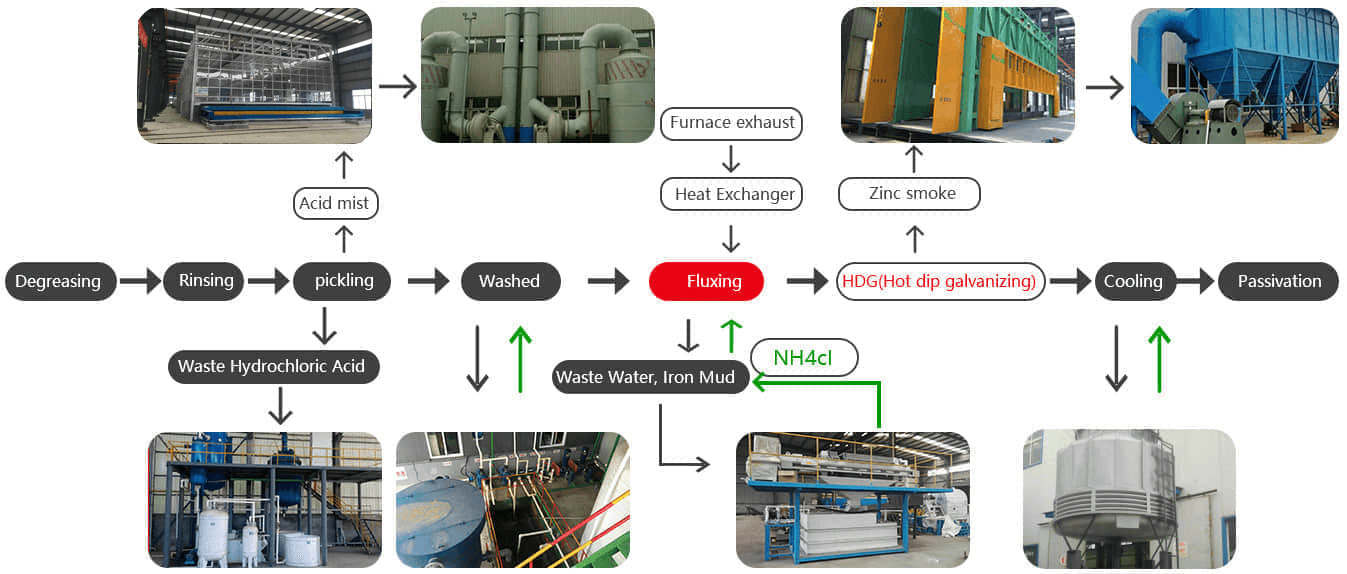

Through the content of the above introduction, we should have correct understanding of hot galvanizing project, so you can pay more attention to our news and information, learn more about hot dip galvanized engineering application and use, etc.

TEL: +86-13703117050 +86-0311-68078187

FAX: +86-0311-84752998

WhatsApp: 0086 137 0311 7050

WeChat: 13703117050

EMAIL: hebeiannuo@163.com

ADDRESS: Shijiazhuang City,Hebei Province, 051530,China