With the continuous development of industry, hot dip galvanized products has been applied to many categories, fixed number of year of the advantage of galvanizing antiseptic and durable, adapt to the environment, has always been a very popular way for prevention of corrosion.

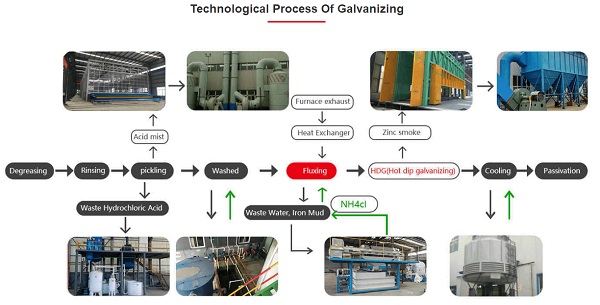

Principle: hot dipped galvanized iron clean clean, then solvent treatment and drying after immersed in liquid zinc, iron and zinc layer of molten zinc has generated a alloying, the process is: degreasing, washing, pickling, helps the plating - drying - hot dip galvanized - separation - cooling passivation.

Of hot galvanizing alloy layer thickness depends mainly on the silicon content of steel and other chemical ingredients, cross sectional area of intrusive, steel steel surface roughness, temperature of zinc pot, zinc dipping time, cooling speed, cold rolling deformation, etc.

1. Low processing cost: the cost of hot-dip galvanizing for rust prevention is lower than that of other paint coatings.

2. Durability: in the suburban environment, the standard hot-dip galvanized anti-rust thickness can be maintained for more than 50 years without repair; In urban or offshore areas, standard galvanized coatings can last 20 years without repair.

3. Good fastness: the galvanized layer is connected with the steel by metallurgy and becomes part of the steel surface, so the durability of the coating is relatively stable.

4. The coating has strong resistance: the galvanized layer forms a special metallurgical structure, which can accept mechanical damage when transported and used.

5. Overall maintenance: each part of the plating can be plated with zinc, which can be fully maintained even in the pits, sharp corners and hiding places.

6. Save time and effort: the galvanizing process is more convenient than other coating construction methods, and it can avoid the time required for painting on the site after the installation.

7, upfront costs low: in general, the cost of the hot-dip zinc is lower than on other maintenance coating, the reason is very brief, other maintenance coating such as sand and paint is labor with, and vice hot-dip zinc process for high mechanization, strict control of construction works in the factory.

8. Simple and convenient inspection: the hot dip zinc layer can be visually and briefly tested by the non-destructive coating thickness meter.

TEL: +86-13703117050 +86-0311-68078187

FAX: +86-0311-84752998

WhatsApp: 0086 137 0311 7050

WeChat: 13703117050

EMAIL: hebeiannuo@163.com

ADDRESS: Shijiazhuang City,Hebei Province, 051530,China